Customer:+86-19182078675 / 19182106357Email:forever@caepforever.com

I.Special tools

Blast burner Fire torch with nozzles Shovel Scissors Steel wire brush Grinder Thermometer pressure roller Abrasive cloth Cotton yarn

II.Rust Removing the Pipe first

a Use grinders to smooth the welding seam and make sure there are no water, oil and other adherent substances on it.

b Shear the pipe exterior coatings on both butt ends to bevel edges, use abrasive clothes or steel wire brushes to scrub the areas of pipe exterior coatings which will connect with heat shrinkable sleeves

c Pipe surface prepared up-to a level of Sa 2 or 2 ½ or St 2/st by mechanical or sandblasting the projectile rust method.

d In order to guard against oxidate of the steel body during the preheat after the burnishing , it is better to make preheat up to 60℃ -80℃ first and then to make rust removing.

III.Prehe at

a Make clean on the patched rim with clean rag, make sure there are no water no rust.

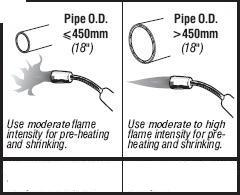

b Ues Fire torch to Make preheat on the patched rim with medium firearms.

c Note: . The preheat should be even. The temperature is at 80℃. If available, the medium-frequency resistance heater can also be used, to pre-heat the pending anticorrosion areas to 80℃.( the temperature is measured with a thermometer)

IV.Heating and contraction

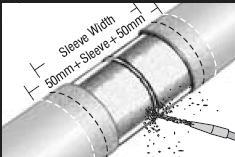

A .Remove the plastic film and lining paper on the heat shrinkable sleeve.Make heating on the adhesive surface at the end with a mark by medium firearms. When the adhesive surface is melting, make it parallel with the pipe as a lap joint on the patched rim . The width of the two sides must be uniform..

B.Make heating on the adhesive surface at the other end with fire .When the adhesive surface is melting, lap joint can be made between the fringe of the end with the mark line on th e other end alignedly . Level is made with a pressure roller.

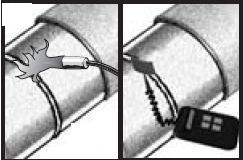

C.Make Heating on the adhesive surface of closure patch with fire(150-170℃),When the adhesive surface is melting, the closure patch is covered onto the mark line. T he lap joint must be even and the width must be equal.

D.Make the closure patch soundly adhered to the girdle with a pressure roller. Make Heating on the closure patch for 2-3 times by medium firearms, and press with a pressure roller for 2-3 times.

E.Start the heat shrinking process from middle and then equably heat the sleeve along its circumference, in order to guarantee the sleeve shrinking flatly, sleeve combing tightly on the pipes and no air entering. After one side is finished shrinking, the other side can be heated 1 The contraction must be even.2 The two fire torches are made at 180 degrees. Bumping each other is not permitted .When the shrink is almost finished, use small flame to heat the sleeve again but completely and equably. The angle of the two fire torches is 180 degrees . The surface temperature is controlled between 150℃to 190℃.The controlling time is 20minutes. In summer it is 15 minutes.

V.Remarks

1.The overlapping width between sleeve and pipe exterior shall be no less than 80cm.

2.The installation should be operated by experienced workers strictly according to the above installation method.

3.The pre-heat temperature of pipes must reach to the required 70-80℃, if the temperature is lower, the adherence between the melting glue and pipes will become loose, which will reduce the exfoliation strength.

4.The sleeve heating should be done evenly, or the overheating of partial area will cause the crack of sleeves.

5. We suggest installing the sleeve when the atmosphere temperature is above 0℃,if the temperature is too low, it will be more difficult for you to preheat pipes.

VI.Cut length of Sleeves ( Suggestion )

Sleeve length | Patch Width | |||

inch | mm | mm | Inch | mm |

3 1/2 | 101.6 | 441 | 4 | 100 |

4 | 114.3 | 484 | 4 | 100 |

5 | 141.3 | 575 | 4 | 100 |

6 | 168.3 | 665 | 4 | 100 |

8 | 219.1 | 856 | 4 | 100 |

10 | 273 | 1037 | 4 | 100 |

12 | 323.8 | 1208 | 4 | 100 |

14 | 355.6 | 1315 | 4 | 100 |

16 | 406.4 | 1485 | 4 | 100 |

18 | 457 | 1655 | 4 | 100 |

20 | 508 | 1827 | 4 | 100 |

22 | 559 | 1998 | 4 | 100 |

24 | 610 | 2169 | 4 | 100 |

26 | 660 | 2337 | 4 | 100 |

28 | 711 | 2509 | 4 | 100 |

30 | 762 | 2680 | 4 | 100 |

32 | 813 | 2852 | 4 | 100 |

34 | 864 | 3023 | 5 | 150 |

36 | 914 | 3191 | 5 | 120 |

38 | 956 | 3332 | 5 | 120 |

40 | 1016 | 3534 | 5 | 120 |

42 | 1067 | 3705 | 5 | 120 |

44 | 1118 | 3906 | 6 | 150 |

46 | 1168 | 4074 | 6 | 120 |

48 | 1219 | 4246 | 6 | 150 |

52 | 1321 | 4588 | 6 | 150 |

56 | 1422 | 4928 | 6 | 150 |

60 | 1524 | 5270 | 6 | 150 |

Note:

Tolerances (out-factory) on Sleeves length are: ±20mm

Tolerances (out-factory) on Patch width are: ±10mm

Sichuan Forever Radiation Technology Co.,Ltd, The main products are 3LPE Heat Shrinkablhke Sleeve, HDD Pipeline Shrinkable Sleeve, 2LPE Heat Shrinkable Tape, 3LPE Heat Shrinkable Tubular Sleeves, Polyethylene Pressure-sensitive Adhesive Shrinkable Sleeve, 3LPE & 3LPP Heat Shrinkable Wrapping Tape, Heat Shrinkable Water-proof End Cap,3LPP Heat Shrinkable Sleeve, Epoxy Primer, Repair Patch, PE Melt Stick, Heat Shrinkable 3LPE Tape For Pre-insulated Pipe, OEM Heat Shrinkable Material Service, Auto-Matic and Manual Type Installation Tools, Irradiation Service, Third Party Inspection Service.

Sichuan Forever Radiation Technology Co.,Ltd

Factory Address 1st : No.403, II Building, 6th Zone, China Science City Industrial Zone, Mianyang City 621000, Sichuan Province, China

Factory Address 2nd : Zhengxing Road Cheng'a Industrial Agglomeration Development Zone, Chengdu City 610000, Sichuan Province, China

WhatsApp : +86 19182078675 FAX : +86-816-2484822 TEL : +86-28-89943988 QQ : 2628226487 www.caepforever.com Email : forever@caepforever.com