Customer:+86-19182078675 / 19182106357Email:forever@caepforever.com

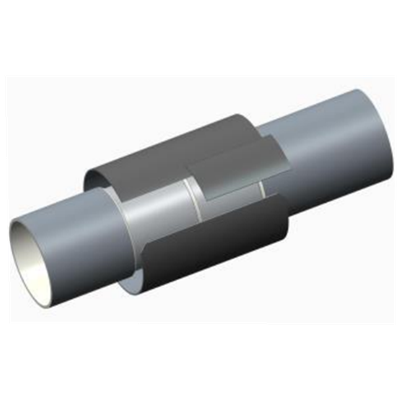

HT60 Heat Shrink Wraparound Sleeves

(Open type sleeves with closure patch)

Technical Data Sheet

Product Profile

HT60 is superior performance heat shrinkable products designed for corrosion protection on field applied girth-weld joints of buried and exposed steel pipelines operating up to 60°C

The inner layer is two-components epoxy primer which coated on steel pipe; Intermediate level is special hot melt adhesive ;

Outer layer is modified radiation crossing linking polyethylene backing.

60°-type heat-shrinkable wraparound sleeve is developed by this Company on the basis of the original product. It is the first of the same kind in China. Currently, the product is well above the domestic anticorrosive professional standards and reaches the standard requirement of EN12068,ISO 21809-3 and ASTM as well.

60°-type product uses the polyethylene produced by ATOFINA of France and many other auxiliary materials as base materials. The mechanic performance targets such as indentation resistance, impact resistance and tensile strength have reached EN12068 standards. And its aging-resistance and ultraviolet rays-proof performance have met the requirements of ASTMD638 standards.

Features & Benefits

● Heat shrink wrap Sleeves provide great corrosion protection, Superior resistance to Cathodic Disbandment and excellent durability against abrasion and chemical attack. The result is effective, good performance of sealing, wide application, easy to operate and preheating temperature,,long term protection against corrosion.

● HT 60 is a wraparound sleeve with a separate closure

● Cross-linked backing provides superior abrasion, mechanical and chemical attack resistance.

● High performance adhesive provides excellent resistance to Cathodic Disbondment to ensure long-term corrosion protection

● Just-in-time customized lengths allow bulk rolls to be field cut top protect any pipe size

● Open sleeve configuration allows the product to be applied after the pipeline has been welded and cleaned.

Product properties | ||

Property | Test Method | Typical Value HT 60 |

Radiation crosslinking PE Backing | ||

Tensile strength | ASTM D 638 | 3200psi (22MPa) |

Elongation | ASTM D 638 | 550% |

Thermal ageing 1) 150°C 21d elongation 2) Tmax +20°C 100d E100/E70 | ASTM D 638 EN 12068 | 420% 1.08 |

Hardness, Shore D | ASTM D 2240 | 52 |

Shrink force | ASTM D 638, 150°C (302°F) | 43psi |

Dielectric strength at 23°C | ASTMD 149 | 825volts/(33KV/mm) |

Moisture absorption | ASTM D 570 | 0.05% |

Hot Melt Adhesive | ||

Softening point | ASTM E 28 | 105°C (221°F) |

Lap shear

| ASTM D 1002 EN 12068, @ 10 mm (0.40")/min. | 196psi (1.35N/mm2) @23°C (73°F) 37 psi (0.25N/mm2) @65°C (149°F) |

Installed Sleeve | ||

Peel to primer @23°C @Tmax | ASTM D 1000

| 130N/cm 25N/cm

|

Cathodic disbandment | ASTM G 42, 30 days EN12068 Class C @23°C @80° | 8mm @ 65°C (149°F) 6mm 8mm |

Hot water immersion | ASTM D 870, 120 days @Tmax | no delamination no blisters or water ingress |

Resistance to thermal ageing (100d/100°C) Peel strength layer to layer P100/PT Peel strength to pipe surface P100/PT | EN 12068, Class C 80 |

3.6 3.8 |

Low temperature flexibility | ASTM D 2671-C | -25°C (-13°F) |

Impact resistance | ASTM G 14 EN 12068, class C | 66 in-lbs >15J no holiday |

Penetration resistance | ASTM G 17, EN 12068, Class C | no holidays @10KV >0.6mm @ 65°C (149°F |

Holiday detection at 5 kV/ mm + 5 kV | EN 12068 ,Class C | no holiday |

Epoxy Primer | ||

Specific Gravity @ 23℃-A -B | ASTM D1963 | ≥ 1.5 <1.0 |

Shelf life | - | 2 Years |

Color(Mixed) | - | Black |

Storage Condition:

● To ensure maximum performance, store these materials in a dry, ventilated area.

● Keep products sealed in original cartons and avoid exposure to direct sunlight, rain, snow, dust or other adverse environmental elements.

● Avoid prolonged storage at temperatures above 40°C or below -20°C .

● Product installation should be done in accordance with local health and safety regulations. Shelf Life: 2 years, under correct storage condition.

Product Selection

Model: HSS-W Φ457*2.0-450 HSS-W: Heat Shrinkable Wraparound Sleeves Φ457------Joint or Pipeline Dimete 2.0---------Thickness 450--------Roll Width (as supplied)

| ||||||

No. | Pipe Diameter mm | Total thickness mm | Backing mm | Adhesive mm | Width mm | Length mm |

1 | 108 | 2.0 2.2 2.5 2.7 3.0 3.5 3.8 4.0 5.0

| 1.2 1.5 1.8 2.0 | 0.8 1.0 1.2 1.5 2.0 3.0 | 400 450 500 520 600 750 1000 | 463 |

2 | 114 | 483 | ||||

3 | 133 | 547 | ||||

4 | 159 | 634 | ||||

5 | 168 | 664 | ||||

6 | 219 | 836 | ||||

7 | 273 | 1017 | ||||

8 | 323 | 1205 | ||||

9 | 325 | 1212 | ||||

10 | 355 | 1313 | ||||

11 | 377 | 1387 | ||||

12 | 406 | 1484 | ||||

13 | 426 | 1551 | ||||

14 | 457 | 1655 | ||||

15 | 478 | 1897 | ||||

16 | 508 | 1998 | ||||

17 | 529 | 2169 | ||||

18 | 559 | 2237 | ||||

19 | 610 | 2337 | ||||

20 | 630 | 2489 | ||||

No. | Pipe Diameter mm | Total thickness mm | Backing mm | Adhesive mm | Width mm | Length mm |

21 | 660 | 2.0 2.2 2.5 2.7 3.0 3.5 3.8 4.0 5.0

| 1.2 1.5 1.8 2.0 | 0.8 1.0 1.2 1.5 2.0 3.0 | 400 450 500 520 600 750 1000 | 2519 |

22 | 711 | 2660 | ||||

23 | 720 | 2832 | ||||

24 | 762 | 3003 | ||||

25 | 813 | 3171 | ||||

26 | 864 | 3342 | ||||

27 | 914 | 3514 | ||||

28 | 965 | 3685 | ||||

29 | 1016 | 1897 | ||||

30 | 1067 | 1998 | ||||

31 | 1118 | 3856 | ||||

32 | 1168 | 4024 | ||||

33 | 1219 | 4196 | ||||

34 | 1321 | 4538 | ||||

35 | 1422 | 4878 | ||||

36 | 1524 | 5220 | ||||

37 | 1626 | 5563 | ||||

38 | 1727 | 5902 | ||||

39 | 1829 | 6245 | ||||

40 | 1930 | 6584 | ||||

41 | 2032 | 6927 | ||||

42 | 2440 | 8298 | ||||

43 | 2600 | 8835 | ||||

44 | 3000 | 10179 | ||||

45 | 3620 | 12262 | ||||

46 | 4852 | 16402 | ||||